Yieldtrac

The YIELDTRAC is the first commercially produced Planter where the planter was designed around the tracks and not the other way around. As a result, the YIELDTRAC provides agronomic performance that is unmatched in the industry and has been doing that since 2012.

The design allows for the strongest frame, yet lightest footprint in the field. Translated that means you can use lighter and/or smaller tractors to pull it; and fully loaded with inputs the YIELDTRAC floats over the soil at only 14 PSI or less.

This design wasn’t by accident. The design team works closely with growers to provide something nobody else in the industry can match: The ability to get into the field sooner; the elimination of pinch rows; and a uniformly balanced toolbar that glides through the field and whose wings bounce 50% less than all others.

So what does this Agronomic design mean for your return on our investment?

- First of all it means we are able to expand your Spring “planting window” by another week because you can get into the field earlier in the Spring and/or after a rain. Hitting your planting windows properly according to Iowa State University Extension Test Trials can mean a 13 to 20 bushel per acre corn impact. Wow, what an insurance policy the YIELDTRAC provides.

- Secondly, eliminating pinched rows. According to a 2011, Pioneer 12 farm Study and a 2011 through 2014 Becks study, the tractor and center section of the planter created pinch wheel compaction that impacted yield on the Pioneer Study of 11.3 bu. and the Beck Study 19.3 bu. (2011) and 17.7 bu. per acre in wetter years and 8.8 bu. and 11.4 bu. per acre (2012-2014) impact in dryer years. The YIELDTRAC eliminates all pinch rows which means the high quality and unique track design as found on the YIELDTRAC will pay for itself with $3 corn in just 1,600 acres.

- Now add a more uniform depth because the wings bounce 50% less. This truly separates the YIELDTRAC from all other planters. Unlike many of you, we didn’t start out brand loyal. So, when looking for a row unit to put on this exceptional toolbar, we had no dog in the hunt. But after looking at the agronomic benefits of the Case IH row unit, we discover over 26 years of evidence that show this row unit providing on average 3 days faster emergence and much higher percentage of uniform plant emergence due to its better accuracy of depth, more consistent soil density around the seed and improved water management. We also discovered that the row unit was less sensitive to and in creating soil compaction that none of the other brands with flat, pushed gauge wheels and one stage closing systems could match. Case IH row units continues to outperform the competitive planting equipment even with all of today’s new technology. Past test have shown a 2 to 10 bu. per acre advantage due to the more uniform depth and improved seed environment. This was the only row unit good enough for the YIELDTRAC. Plus, YIELDTRAC makes the Row Unit even better by lowering wing bounce 50% and improving seed spacing and depth placement at higher speeds!

So what does it all mean in summary? The YIELDTRAC will help you hit your planting windows, increase photo-copy plant emergence and eliminate pinch rows—impacting yields approximately 15 to 20 bu. per acre. Indeed, imagine what you could do with an additional $45 to $60 per acre. We try to put ourselves in your shoes. If we were making an investment of this magnitude, we’d be looking for the fastest and largest return on our investment. The YIELDTRAC is unmatched in the speed and size of the return you will receive. Happy and Successful Planting! Thanks for considering a YIELDTRAC.

Models

|

24R20 |

16R30 |

32R15 |

24R22 |

24R30 |

36R20 |

48R15 |

36R22 |

| Transport Width |

|

|

|

|

|

|

|

|

| 1200 Series RU |

14’ 6" |

N/A |

16’ 3" |

14’ 6" |

14’ 6" |

16’ 2" |

16’ 3" |

14’ 6" |

| 2000 Series RU w/ Closing Wheel not Folded |

15’ 5" |

15’ 5" |

17’ 1" |

15’ 5" |

15’ 5" |

16’ 2" |

17’ 1" |

15’ 5" |

| 2000 Series RU w/ Closing Wheel Folded |

14’ 8" |

14’ 8" |

15’ 0" |

14’ 8" |

14’ 10" |

16’ 2" |

15’ 0" |

14’ 10" |

| Transport Length |

36’ 5" |

36’ 5" |

37’ 3" |

36’ 5" |

47’ 5" |

47’ 5" |

48’ 3" |

47’ 5" |

| Transport Height w/ Markers |

11’ 2" |

11’ 2" |

11’ 2" |

11’ 2" |

12’ 2" |

12’ 2" |

12’ 5" |

12’ 2" |

| Engine Power Requirements |

260 HP |

240 HP |

300 HP |

260 HP |

260 HP |

340 HP |

380 HP |

340 HP |

| Drawbar Requirements |

CAT 4 |

CAT 4 |

CAT 4 |

CAT 4 |

CAT 4 |

CAT 5 |

CAT 5 |

CAT 5 |

| Hydraulic Requirements |

45 GPM |

40 GPM |

50 GPM |

45 GPM |

45 GPM |

50 GPM |

57 GPM |

50 GPM |

| Planter Weight (lbs.) |

|

|

|

|

|

|

|

|

| 1200 Series RU |

31,800 |

N/A |

33,500 |

31,500 |

34,500 |

38,500 |

43,600 |

38,700 |

| 2000 Series RU |

32,400 |

29,600 |

35,900 |

32,500 |

36,900 |

41,600 |

47,300 |

41,800 |

Our Flagship 48R 15” Planter—48 rows at 15” spacing; Exclusive Centering Toolbar for 30”planting; Carries 750 Gallon of Liquid Fertilizer and 120 Bushel of Seed.

24R 30” (Right) 120 Bushel Seed Capacity 750 Gallons Standard and 36R 22” (Left) 120 Bushel Seed Capacity and 750 Gallon Fertilizer Standard.

16 Row 30” Case IH 2000 Series Row Units, Liquid Fertilizer, 120 Bus. Seed Capacity

32R 15” With Case IH 1200 Series Row Units Set-up to do 15” Corn and optional Hydraulic Drawbar Hitch and Rear hitch

36R 22” 120 Bushel Seed Capacity and 750 Gallon Fertilizer Standard with Optional Markers

Fold and Unfold Anywhere. Fast, Efficient, and Narrow. This Front Fold will Surprise and Exceed Expectations.

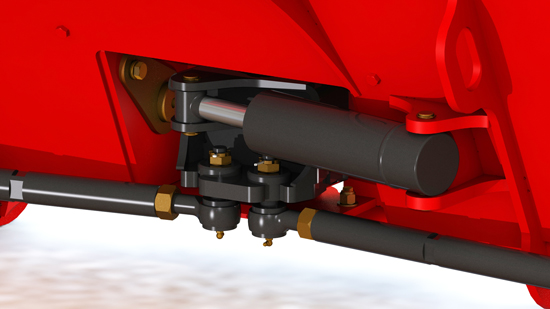

Wing, Power Fold Drive Motors allows this front-fold planter to be folded/unfolded in almost any terrain while taking 1000 lbs. off the center-section for a lighter footprint. But more importantly, note where the power is pulling from—the end of the wing providing better leverage, protecting the bar hinge points, and allowing for greater strength with less weight.

There is a reason for Its Name—YIELDTRAC!

These Tracks are not an add-on or purchased from someone else. These tracks are designed and built by Norwood. The designer of these tracks was also responsible for designing tracks for the Steiger QuadTrac so, you know these tracks are head-and-shoulders above the rest. This was the first commercially produced planter toolbar designed with totally integrated tracks, lightening the footprint of a fully loaded planter to only 14 PSI or less, nearly eliminating the yield robbing compaction of wheeled planters saddled with 65 to 90 PSI tire pinch rows.

These tracks feature a +/- 5 degree camber arching and lock system that allows the track to maintain a full footprint on crowned roads while still maintaining a full footprint in the field on turns and hillsides. A full crowned road footprint also means that these tracks can transport at the legal speed of the tractor pulling a load that doesn’t have auxiliary brakes. Comes in 18” or 24” Track Widths.

Track Spacing: Center-to-Center

120” Standard and 88” Optional for 30”/20”/15” Rows

88” Standard and 132” Optional for 22” Rows

But Starting with a clean slate to build an agronomically correct toolbar didn’t stop with tracks. This Birds-eye View will help you see why. It allowed us to provide more strength, performance and reliability without adding weight. An important factor for improved yields and planting more acres per hour!

The clean and open design of this planter make it one of the most easily customizable planters on the market. It is organized, everything has a place and the fit and finish is unmatched in the industry. Compare this look with the others.

These Planter Shields give the planter a clean organized look and protect against weather especially when you have to leave the planter in the field when you are a long way from home.

The Shields effortlessly swing up out-of-the-way for quick and easy access. The electronics are protected from water and the Shield’s structure and housing provides attachment points to provide superior organization of components and a consistency of assembly unrivaled in the industry.

Equipment and features that accommodate your farming style while giving you more options to meet the changing “art” of planting.

Fertilizer is Standard and uses the latest Case IH pump and manifolds. Tanks sizes are 500 and 750 gallon. Additional sizes may be available. A fertilizer deduct for those not needing fertilizer is also available. We will work with your dealer for placement options. Fully loaded YIELDTRAC w/Fertilizer still provides a 14 PSI or less footprint.

Case IH 2000 Series Row Units are available with Electric Drive Meters and In-Cab Pneumatic Closing Disc supported with a Deluxe Air Compressor as standard. You choose either Pneumatic or Hydraulic Row Unit Down-Pressure and Wide or Narrow Pulled Gauge Wheels as options. Advanced Seed Delivery System is also an option.

Case IH 1200 Series Row Units are available with the Advance Seed Meter (ASM), Hydraulic Drive, Electric Row Shut-off, and In-Cab Row Unit Pneumatic Down-Pressure on all models except the 48R-15 and 32R-15. The 1200 Series can also come with Precision v-Set II Electric Drive Meters and Delta Force Row Unit Down-Pressure and this combination is available on all models including the 32R-15 and 48R-15.

Optional Factory Installed Row Cleaners come in either Manual Floating Tine or No-Till Row Versions. In addition you can get Precision’s Clean Sweep on both versions of Row Cleaners allowing for In-Cab setting adjustment.

Optional Markers are available for every Configuration to serve as guidance insurance, to help map difficult field boundaries and/or end-of-day—last pass confirmation to start next day’s work when using guidance systems where satellite orbits reposition their signal overnight.

Optional Hydraulic Drawbar Hitch is highly recommended for those Growers that have difficult Field Entrances. It provides additional clearance under the toolbar when going into or coming out of steep inclines. It also allows the operator to make manual, minor in-field bar pitch adjustments when traversing terraces or crowns in the field. Additionally, it serves as an Hydaulic Jack when parking or storing the Planter.

Optional Rear Hitch to pull auxiliary tanks and additional inputs stretching capacities to new levels. Centered mounted with electrical connectors.

Optional In-field, Steering Ready Tracks: YIELDTRAC provides the hardware to allow you to attach your guidance system of choice. This gives you control to prevent slope drift on the most severe grades. +/- 13 degree correction capable.

Optional Centering Toolbar—Another YIELDTRAC Exclusive: All our planters that are used as Split-row planters i.e. 48R 15 (24R 30” or 48R 15” Row Spacing); 32R 15 (16R 30” or 32R 15” Row Spacing); have the ability to side-shift the toolbar from the tractor cab by just pushing a button. That way you are always pulling from the center of the tractor. Planter draft is always equalized and from a guidance system standpoint, you can enter and start the field from any direction. Three cylinders across the width of the Planter shifts the bar 7.5 inches to re-center it for 30” corn.

Monitors/Controllers

The Case-IH Pro-700 monitor, sold separately, runs the toolbar fold functions and the fans. It runs all functions on the 1200 series row units with ASM meters, pneumatic down pressure, electric row shut-offs, hydraulic drive, and fertilizer. When looking at the 32R15 and 48R15 with 1200 series row units, it will use the 20/20 Seed Sense monitor in conjunction with the Pro-700 to control the electric drive meters and hydraulic down pressure.

For planters with the 2000 series row unit, electric drive meters are standard and all planter functions are controlled through the Pro700 monitor. The 20/20 Seed Sense display can be optionally installed on all models to control the electric drive meters and hydraulic downpressure, but is required for operation on 36-row and larger units. All Yieldtrac planters with the 2000 series row unit are compatible with Dual CAN operation for the Gen 3 20/20 Seed Sense Display.

Clean Sweep uses its own Controller on 1200 series row units’ and is part of the Clean Sweep Package. Clean Sweep is controlled by the Pro700 on 2000 series row units.

It is More than Just Tracks

We understand that it’s not about the “tracks”, but about your livelihood. That means, doing everything possible to mechanically enhance the seed environment and to optimize “yield” potential, is job one. You can mess with all the data you want. You can write sophisticated fertilizer and seed, variable rate prescriptions, but if you can’t put the seed in the correct place in an optimize soil environment at the right time, all the time spent with the data and prescriptions are wasted.

In the real world, where the work gets done, we are unmatched in placing the seed in the correct place, minimizing and/or eliminating compaction, and optimizing the seed’s soil environment—improving your “yields” in real live hard bushels. No theories, no hype, just “real life” execution in the soil where yield begins…………………………………

And that’s why we call it “YIELDTRAC”!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Videos